[1].Feature

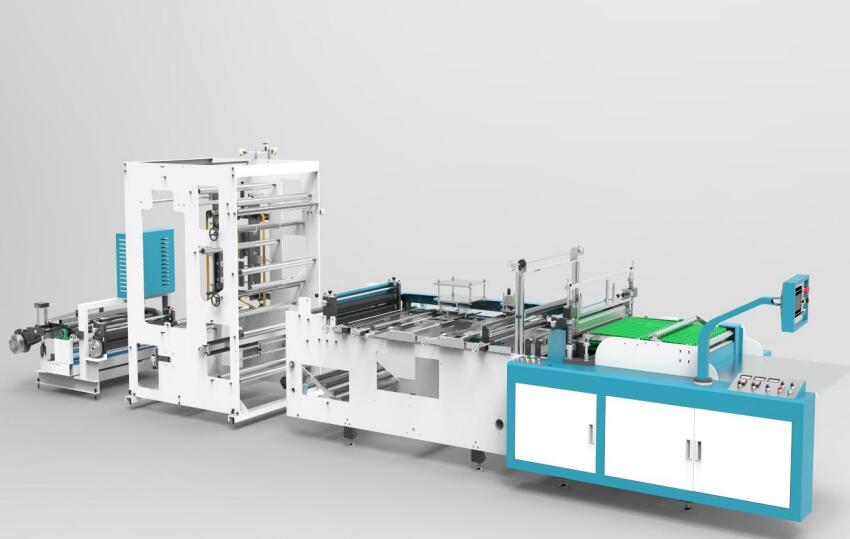

1) This machine has following functions: edge-folding, end-folding, heat-fitting, spot-cutting, drilling, welding, and heat-cutting. It can be used to manufacture various types of clip-chain sealing bags, such as inside heat-fitting with spot-cutting, outside heat-fitting with locks.

2) This machine has used advanced computer-controlled, liquid crystal display and automatic serving motor-driven.

3) It can cut clip-chain and film, automatically alarm, shut down automatically when no material, stop printing automatically when electric eyes lapse, stop working automatically when temperature is not enough, and fold edges by using photoelectric corrective hemming and magnetic tension.

4) This machine operates easily, seals firmly and has quality appearance.

5) The whole procedure is operated automatically from single film raw material to electric eyes correcting, edge folding, end folding, zipper fitting, pasting, edge welding, edge cutting, ultrasonic wave, electronic eyes printing, drilling, heat cutting, and automatically counting.

[2].Main Technical Specification

|

Model |

ZK-800C |

|

Raw Material |

PP, LDPE,HDPE |

|

Bag Making Width |

100-800mm |

|

Bag Making Length |

100-650mm |

|

Bag Making Speed |

40-80cuts/min. |

|

Film Thickness |

0.04-0.15mm |

|

Servo motor |

2.8KW |

|

Main motor |

1.5KW |

|

Feed motor |

0.75KW |

|

Heating power |

3.8KW |

|

Ultrasonic |

1set |

|

Conveying motor |

0.5KW |

|

Folding motor |

0.55KW |

|

Cooling motor |

0.55KW+0.25KW |

|

Voltage |

380V, 50HZ, 3phase |

|

Total Power |

18KW |

|

Install dimension |

8.5×1.7×1.8m |

|

Total Weight |

2200KGS |