Characteristic

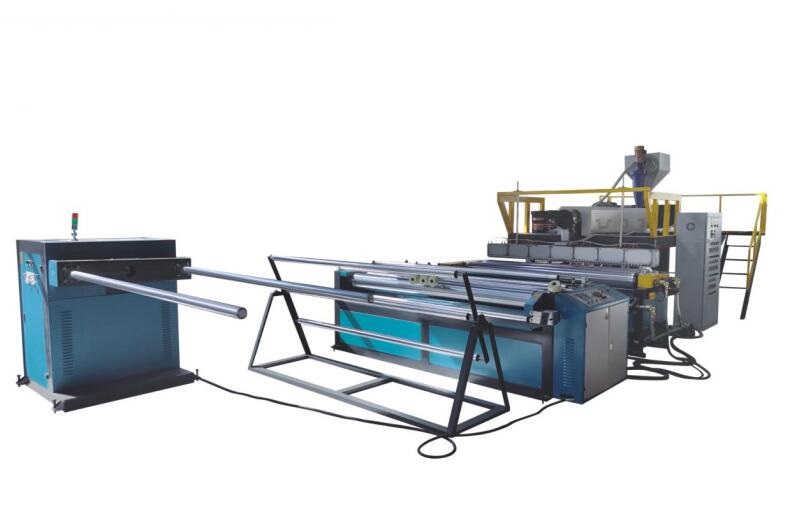

This machine adopts once-through shaping technique, thus has high efficiency and excellent product quality.

This machine set has such features as scientific and reasonable structure design, smooth and reliable running and convenient operation and maintenance.

Polyethylene air-cushion film (also called polyethylene bubble film), which is divided into two kind: ordinary polyethylene air-cushion film and composite polyethylene air-cushion film, is a kind of packing material which has been widely used at present.

It not only has good cushioning effect, shock resistance and heat-sealing performance, but also has such advantages as good corrosion resistance and transparency, etc.

Application:

The bubble film is made of LDPE material.It can also make into laminated films with aluminized film, foamed PE sheet, and paper are the applications of sun shading, heat insulation, and packaging.

Main Technical Specification

|

Model |

HSQP-1500 |

HSQP-2000 |

|

Main material |

LDPE |

LDPE |

|

Screw diameter |

75mM |

90mm |

|

Mold width |

1700mm |

2100mm |

|

L/D ratio |

28:1 |

28:1 |

|

Main motor |

22KW |

30kw |

|

Heating power |

22KW |

32kw |

|

Finished film width |

1500mm |

2000mm |

|

Rewind diameter |

1000mm |

1000mm |

|

Main bubble specification |

10×4mm/6×3mm/20×10mm |

|

|

Output capacity |

60-80kg/h |

80-120kg/h |

|

Power source |

380V,3phase |

|

|

Total installed capacity |

60KW |

80KW |

|

Overall dimension |

6×3×2.5m |

7.5×3.3×2.5m |

|

Gross weight |

4500KG |

6000KG |